E-mail:sales@bestchickencage.com

E-mail:sales@bestchickencage.com

YOU LOCATION:Home > Products > Battery Cage

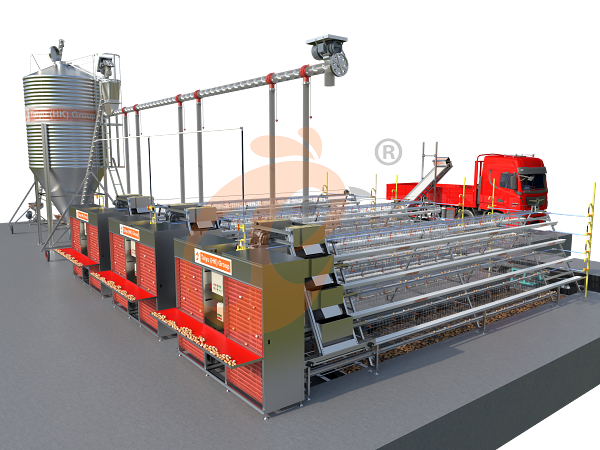

A Type Automatic Layer Battery Cage For Sale:

Design, Types, Size, Structure, Advantages, Data, And Price

A type automatic layer battery cage is an A-frame structured poultry cage system designed for commercial egg production.

10,000–50,000 layers poultry farm choosing it.

Hot Sale Commercial Dimension

Hot sale type:

1. Tiers: 4 tiers

2. Capacity/set: 160 chickens

3. L X W X H: 2.2m by 3.0.m by 1.75m

4. House Size: 50 × 14 × 4.25–5.65 m (L × W × H), 8,640 birds

5. House Size: 100 × 14 × 4.25–5.65 m (L × W × H), 19,680 birds

What Is The Structure Of Battery Cage?

The popular A type battery cage design

Here is a shorter video introducting its whole structure such as cage frame, automatic sytem of watering, feeding , egg collection and theirs working principle.

Easy Tips To Choose Right Layer Battery Cage

| Comparison Item | A-Type Manual | A-Type Automatic | H-Type Automatic |

|---|---|---|---|

| Structural Type | A-type stepped structure | A-type stepped structure | H-type vertical stacked structure |

| Capacity Per Poultry House | 1,000–30,000 birds | 10,000–60,000 birds | 50,000–300,000+ birds |

| Scalability | Limited | Moderate | Very high |

| Suitable Farm Type | Small or start-up farms | Medium-scale commercial farms | Large-scale industrial farms |

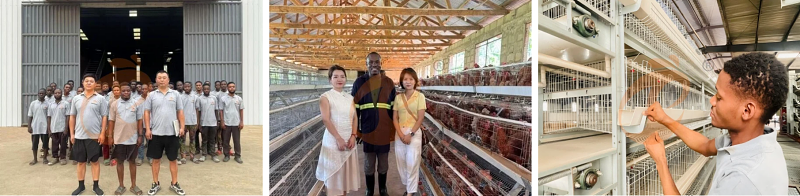

Nigeria-China Local Leading Battery Cage System Manufacturer And Supplier

Vanke Machinery And Equipment CO., LTD

We started in 2011, Our poultry battery cage and poultry farm equipment are selling in 90% Nigerian states.

Lagos office: After Sinoma Office, 200 Meters Near Danco Filling Station, Lagos/Ibadan Expressway, Lagos State, Nigeria.

1. Lagos local factory & technical team in Nigeria

2. Faster installation & after-sales response

3. Reduced shipping time and import pressure

4. Designs optimized for Nigerian poultry farming conditions

Why Choose Vanke's A Type Automatic Layer Battery Cages?

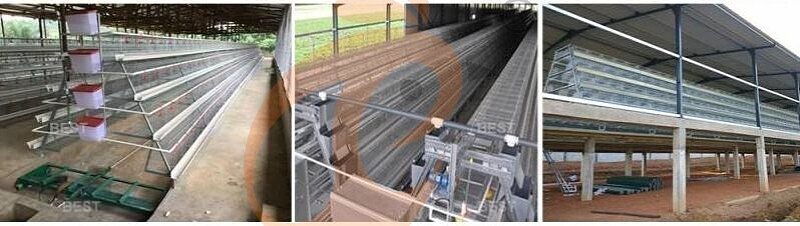

Vanke's Battery Cage System In Nigerian Poultry Farm

Vanke's Design:

1. Optimized ventilation and manure removal design helps reduce heat stress and ammonia levels under Nigeria’s high-temperature and high-humidity climate.

2. A-Frame vertical structure to maximize poultry house capacity, especially suitable for Nigeria farms where land cost is rising around major poultry areas such as Ogun, Oyo, and Lagos States.

3. Scientific cage slope (6–7°) ensures smooth egg rolling and reduces egg breakage.

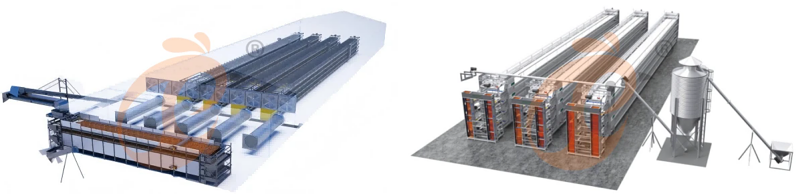

A Type Layer Battery Cage Layout

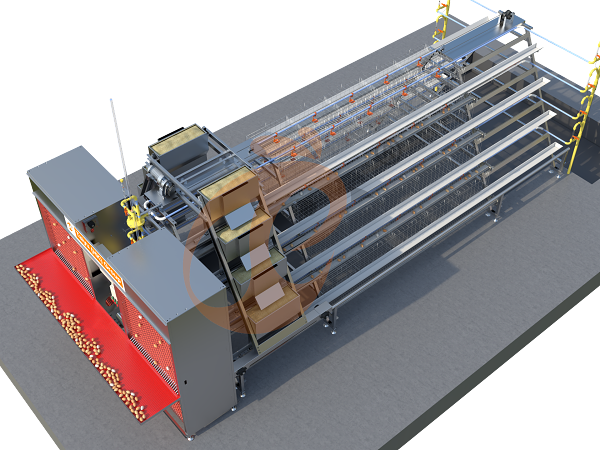

45 Degree Overlooking View

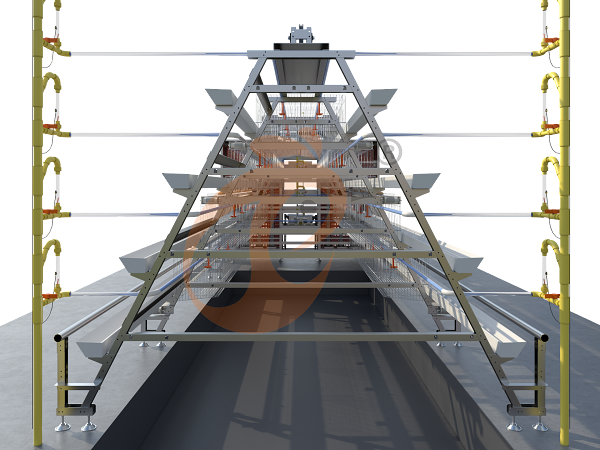

Parallel View

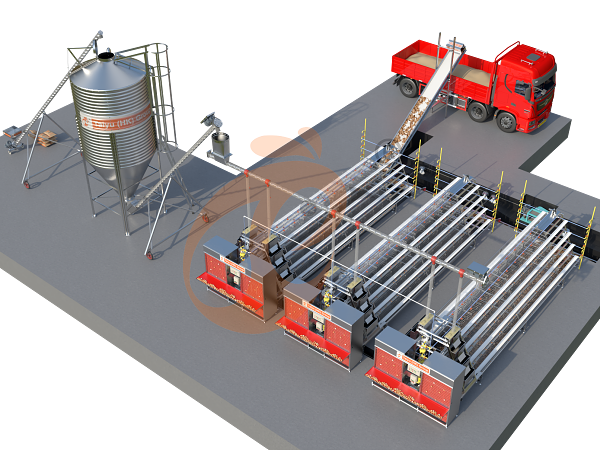

Top View

A shorter video to help you learn it faster

Detailed Structure

Our battery cage poultry farm case, watch its practice application more clearly

| No. | System / Component | Main Material/Parts | Function | Key Parameters |

|---|---|---|---|---|

| 1 | Cage Frame And Wire Mesh | Q235 low-carbon steel, hot-dip galvanized | Provides a stable and safe living space for laying hens | Corrosion-resistant surface |

| 2 | Automatic Feeding System | Feed hopper, spiral auger or chain feeder, feed trough | Automatically delivers feed evenly to each cage row | Feeding accuracy ±2% |

| 3 | Automatic Nipple Drinking System | Water tank/pressure regulator, water pipes, stainless steel nipple drinkers | Supplies clean and hygienic drinking water continuously | Flow rate 60–80 ml/min per nipple |

| 4 | Automatic Egg Collection System | PVC or PP egg belts, belt rollers, egg collection table | Gently collects and transfers eggs to a central area | Egg breakage rate <1.5% |

| 5 | Automatic Manure Removal System | Manure belts, manure scrapers, transverse conveyor | Regularly removes manure to keep cages clean | Operation 1–2 times/day |

| 6 | Control And Drive Accessories | Motors, reducers, sensors, control panels | Drives and controls all automatic systems | Stable and synchronized operation |

Price Of Layer Battery Cage For Sale

The price depends on:

1. Automation configuration level

2. Cage material thickness and galvanization standard

3. Poultry house size and layout

4. Optional control systems

Reference Price Range:

USD 2.5–3.2 per bird, depending on configuration

Related Equipment Of Poultry House And Farm

House Environmental Stability

1. Ventilation systems maintain the house temperature between 18–26°C.Poultry house management (selective assembly)

Farm management APP

Control device and sensors

If you are interested in other equipment of AI smart management, layers, broilers, pullets, feed, eggs, manure and so on, please directly click PRODUCTS

| Type | Tier/Set | Size(L x W x H)/Unit(M) | Cell Size(L x W x H) (CM) | Cells/Unit Per Set | Birds/Cells | Birds/Set | Space/Bird(CM2) |

| A1 | 3 | 2.2 x 2.4 x 1.85 | 43 x 38 x 38 | 30 | 4 | 120 | 418 |

| A2 | 4 | 2.2 x 2.4 x 2.2 | 43 x 38 x 38 | 40 | 4 | 160 | 418 |

| A3 | 5 | 2.2 x 2.4 x 2.8 | 43 x 38 x 38 | 50 | 4 | 200 | 418 |

House size and birds capactiy

| Component | Regular Data | ||

| Cage Model | 3 tiers | 4 tiers | 5 tiers |

| House Size: 50 x 14 x 4.25-5.65 (L x W x H) | 6,480 birds | 8,640 birds | 10,800 birds |

| House Size: 100 x 14 x 4.25-5.65 (L x W x H) | 14,760 birds | 19,680 birds | 24,600 birds |

| Standard Cage Dimension (L x W x H) | 2.2 x 2.4 x 1.75m | 2.2 x 2.4 x 2.2m | 2.2 x 2.4 x 2.65m |

| Birds Per Set | 120 birds | 160 birds | 200 birds |

For reference only, the exact size is based on the actual needs of the poultry farm and customer requirements, or our exact quotation.

1. Since its establishment in 2011, we have rich experience in localization services.

Nigerian local team

2. Constant communication with the United States and Europe, make high-quality battery cage and equipment.

Engineer inspection

3. Lagos local production, save customers 10% to 30% of costs.

Nigerian Factory, workshop and materials

4. Constantly innovate technologies, tailor intelligent project solutions for you.

Intelligent solution

5. Constantly expanding the team, the headquarters in Hong Kong and branches in Nigeria, Tanzania and Ethiopia are joint management.

Branches of China, Nigeria, Tanzania and Ethiopia

Vanke Machinery & Equipment Nig Ltd have serviced farmers and distributors since 2010.

Gain the high trust and recognition from customers to now.

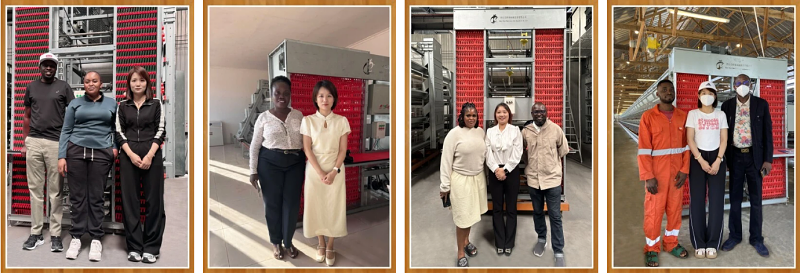

Following farmers are some of our clients, welcome you!

Contact: Whatsapp 24 hours online +234 8111199996.

ADD: after Sinoma Office, 200 meters near Danco Filling Station, Lagos/Ibadan Expressway, Lagos State, Nigeria.

7 Detailed Advantages Of Battery Cage System

1. Significant Labor Cost Reduction (50–70%)

By integrating automatic feeding, drinking, manure removal, and egg collection systems, the fully automatic A type layer cage dramatically reduces manual operations.

Labor requirement reduced by 50–70%

One worker can manage 20,000–30,000 laying hens

This advantage is especially critical in regions facing rising labor costs and labor shortages.

2. Higher Stocking Density And Space Utilization (Up To 3 Times)

The A-frame vertical structure allows full use of poultry house height.

Stocking density: 18–25 layers per square meter

Floor raising systems: 6–8 layers per square meter

Space utilization improved by 2.5–3 times

As a result, farmers can either raise more birds in the same building or reduce construction costs for new poultry houses.

3. Improved Egg Production Performance (5–8% Increase)

Standardized cage environment and precise feeding significantly improve laying performance.

Egg laying rate increases by 5–8%

Annual egg production: 280–320 eggs per hen

Egg size uniformity improved by 10–15%

Stable nutrition intake and reduced stress help hens maintain peak production for a longer period.

4. Better Feed Conversion And Lower Feed Waste (3–5%)

Automatic feeding systems ensure uniform feed distribution.

Feed conversion ratio improves by 3–5%

Feed waste reduced by 10–15%

Annual feed cost savings: USD 8,000–15,000 for a 20,000-layer farm

Since feed accounts for 60–70% of total production cost, even small improvements bring significant economic benefits.

5. Lower Egg Breakage Rate And Better Egg Quality

The scientifically designed cage bottom slope and gentle egg belt transportation protect eggs during collection.

Egg breakage rate controlled below 1.5%

Manual collection systems typically: 3–5%

Clean egg rate increased by 15–20%

This directly increases the percentage of marketable eggs and improves selling price.

6. Improved Poultry House Environment And Biosecurity

Automatic manure removal reduces waste accumulation and harmful gases.

Manure removal frequency: 1–2 times per day

Ammonia concentration reduced by 40–60%

Disease incidence reduced by 20–30%

A cleaner environment leads to lower mortality rates and reduced veterinary expenses.

7. Long Service Life And Low Maintenance Cost

High-quality materials ensure long-term durability.

Hot-dip galvanized steel coating: ≥275 g/m²

Service life: 15–20 years

Annual maintenance cost reduced by 20–30% compared with ordinary cages

Modular accessories allow easy replacement without stopping the entire system.

1. All fittings are packed by wooden pallets and boxes, plastic wraps and boxes, nude packing, it depends.

2. Local factory and warehouse from branches of Ethiopia, Tanzania and Nigeria, depends on your order.

3. Full or less container from China branch by sea, depends on your order.

Nigerian factory, warehouse and delivery

Container shipping from China to Nigeria

Engineer installation In Nigeria

10 Essential Maintenance Tips For Layer Battery Cage System

1. Cage Frame Inspection

Action: Check all cage frames, partitions, and wire mesh for corrosion, deformation, or loose bolts.

Frequency: Every 3–6 months.

Tip: Re-tighten loose bolts, replace damaged mesh, and apply anti-rust coating to maintain structural stability.

2. Feed System Cleaning And Lubrication

Action: Clean feed hoppers, augers, and chain conveyors to prevent blockages and bacterial growth. Lubricate motors and moving parts.

Frequency: Cleaning monthly; lubrication every 2–3 months.

Tip: Avoid contaminating feed channels with excess lubricant.

3. Nipple Drinking System Maintenance

Action: Inspect water pipelines, check water pressure, and clean nipple drinkers.

Frequency: Weekly visual check; deep cleaning every 1–2 months.

Tip: Maintain flow at 60–80 ml/min per nipple and ensure no leaks or clogging.

4. Egg Belt And Collection System Check

Action: Check egg belts, rollers, tension devices, and egg collection tables for wear or misalignment. Remove debris.

Frequency: Daily visual inspection; monthly full check.

Tip: Adjust belt tension to prevent egg breakage and ensure smooth egg transport.

5. Manure Belt And Scraper System Maintenance

Action: Inspect manure belts, scrapers, and transverse conveyors for wear, tear, or motor problems.

Frequency: Daily quick check; monthly detailed inspection.

Tip: Keep belts dry and free from obstruction to maintain hygiene and reduce ammonia concentration.

6. Motor And Drive System Check

Action: Inspect all motors, gearboxes, chains, and reducers for unusual noise, vibration, or overheating.

Frequency: Monthly; after any abnormal operation.

Tip: Ensure proper lubrication and tighten motor mounting bolts to prevent mechanical failure.

7. Control Panel And Electrical Components

Action: Inspect control panels, wiring, switches, and sensors for damage or corrosion. Ensure proper grounding and protection.

Frequency: Quarterly visual inspection; immediately if system alarms occur.

Tip: Keep control panels dry and dust-free; replace faulty sensors promptly to avoid system downtime.

8. Cage Floor And Mesh Cleaning

Action: Remove dirt, feathers, and debris from cage floors and mesh to prevent bacterial growth and maintain hen health.

Frequency: Weekly; more often during peak production or high humidity seasons.

Tip: Use mild disinfectant to prevent chemical residue while maintaining hygiene.

9. Lighting And Ventilation System Check

Action: Ensure lights are functioning and evenly distributed. Inspect fans, vents, and air inlets for blockages or wear.

Frequency: Monthly; weekly visual check recommended.

Tip: Proper lighting and airflow maintain laying performance and prevent heat stress.

10. Routine System Test And Calibration

Action: Run full system tests for feeding, drinking, manure removal, and egg collection. Adjust timers, sensors, and belt speeds as necessary.

Frequency: Every 3 months or after major maintenance.

Tip: Keep a log of system performance metrics to track efficiency, egg breakage rates, and feed consumption.

SEND YOUR MESSAGE TO US

(* We will reply your inquiry to this Email as soon as we see it.)RECENT BOLGS

Comments

CONTACT US